The Challenge

The plant had zero prior exposure to Lean principles after 100+ years of traditional operations. Leadership wanted to start introducing Lean thinking but struggled to capture any attention or buy-in from the workforce stuck in a “why change?” mindset. No internal SMEs existed, and the Director of Operations needed a subtle way to spark interest without disrupting the busy floor.

The Approach

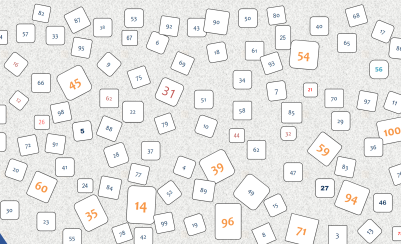

Knowing a large-scale live session was a non-starter, I designed a concise, 15-minute gamified eLearning experience focused on 5S fundamentals. The goal was to create an engaging, memorable introduction that respected the realities of floor time constraints while simulating real workplace scenarios to build relevance and buy-in.

Introducing 6S

This simple game introduced the manufacturing floor staff to 6S in an interactive way.

The Outcome

Initial resistance was strong. Many operators felt the challenge was too hard and unrealistic. However, as they applied the concepts on the floor, they realized the training mirrored real improvements.

The plant floor visibly improved, demonstrating that this simple gamified approach succeeded in both educating and motivating staff to embrace Lean in a way traditional methods had not.